120V Electric Motor Wiring Diagram Wallpapers

Related Images

More Images

Explore Topics 1

- Honda Cm400A Wiring Diagram

- Nissan Quest Wiring Diagram

- Wiring Diagram 2004 Audi All Road

- Relay Circuit Schematic Diagram

- E310Ac Wiring Diagram

- 2007 Toyota Solara Fuse Box Diagram

- Dodge Magnum Headlight Diagram

- 2005 Chevy Equinox Wiring Diagram

- Car Horn Wiring Diagram With Relay

- Toyota Ta Fuse Box Diagram

Explore Topics 2

- Kawasaki Fuse Box Diagram

- Wiring Diagram Kia Carnival 2 9 Crdi Espa Ol

- 2008 Chevy Silverado 15010Radio Wiring Diagram

- 20010Chrysler 300M Fuse Diagram

- Stop Light Wiring Diagram 1997 S10

- Mercruiser Engine Diagram Belt

- Renault Clio Horn Wiring Diagram

- Circuit Diagram Zone Valve

- Spst Wiring Diagrams Seymour Duncan Stratocaster

- 3 Kicker Cvr 12Series Wiring Diagram

Explore Topics 3

- Seymour Duncan Wiring Diagrams Dp123

- Superior Body Diagram Unlabeled

- Ceiling Fan Wiring Diagram 3 Way Switches

- 3 Wire Submersible Pump Wiring Diagram

- Dutchmen Rv Wiring Harness Diagram

- 1999 Chevy S110Wiring Diagram

- Meyer Plow Wiring Diagram 2003 Silverado

- 2008 Civic Fuse Box Diagram

- 2007 Toyota Matrix Fuse Box Diagram

- 1993 Chevy Silverado 15010Wiring Diagram

Explore Topics 4

- Schneider Electric Motor Starter Wiring Diagram

- Ford F 2510Cooling System Diagram

- 2005 Triumph Rocket 3 Wiring Diagram

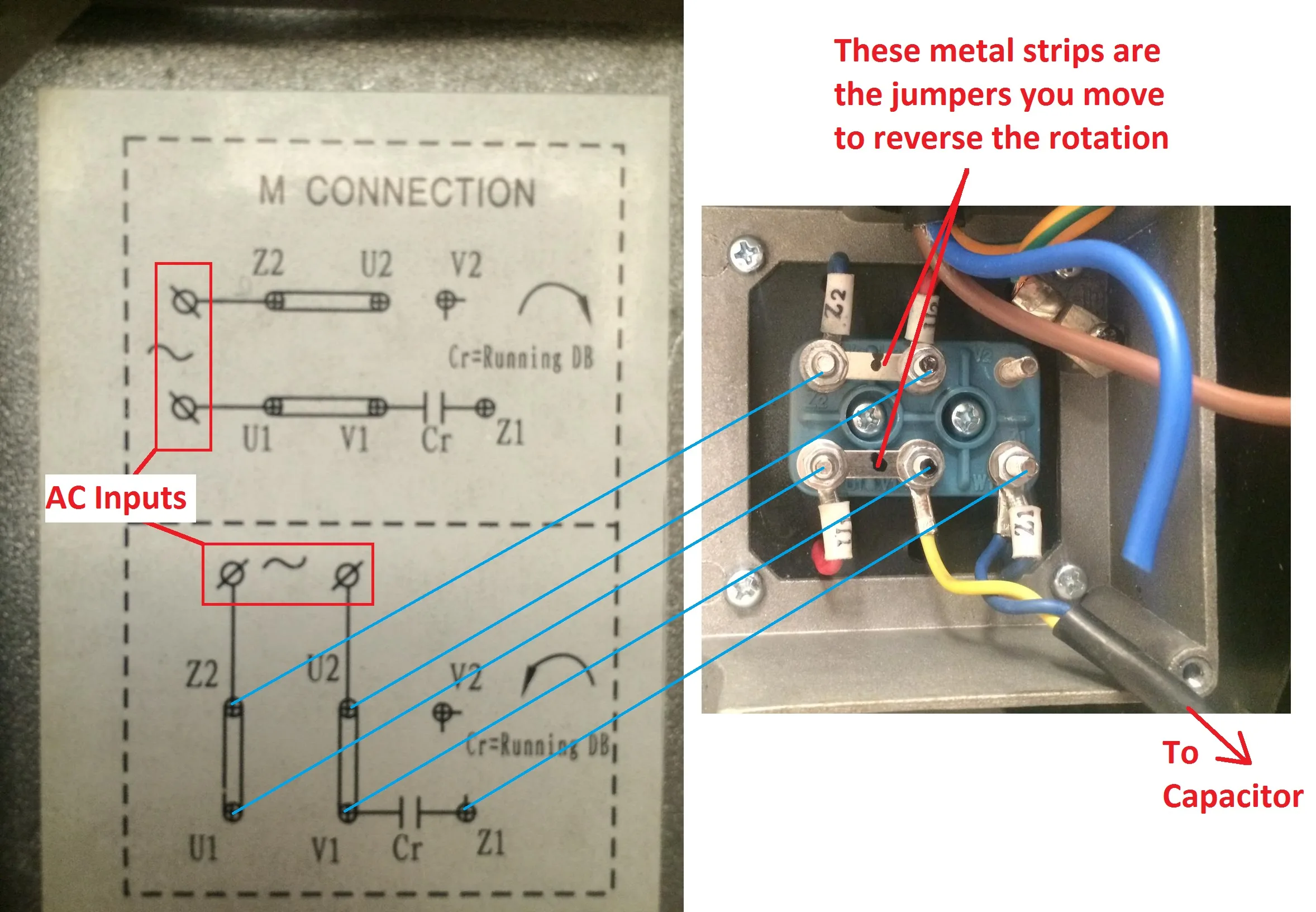

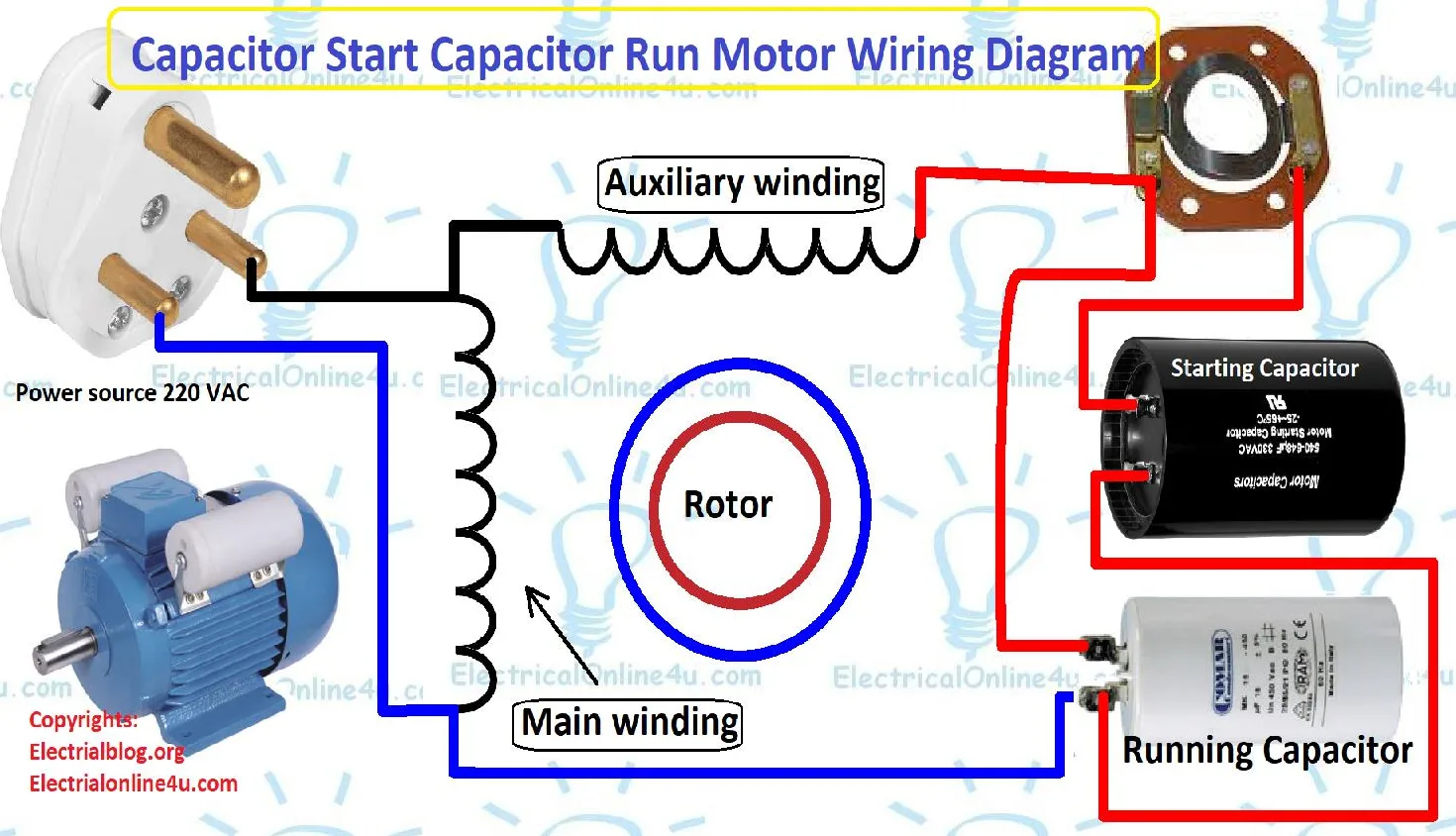

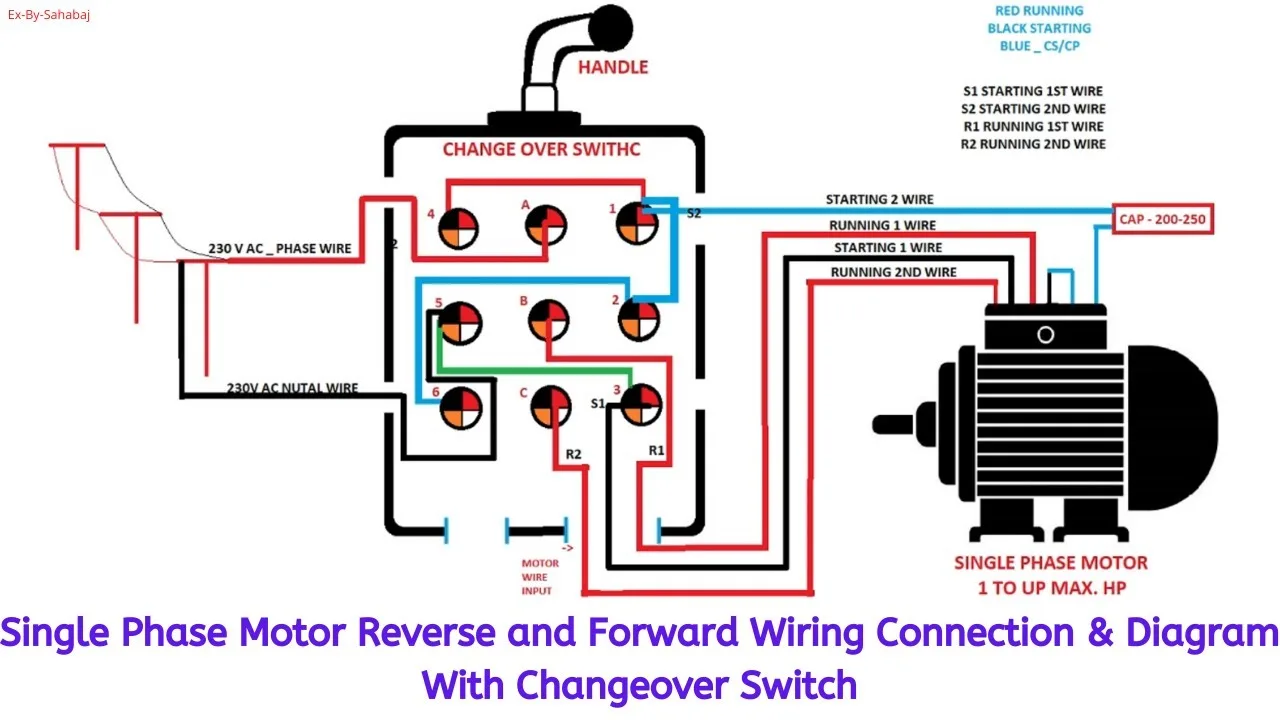

- Wiring Diagram For Single Phase Motor

- 2001 Chevy S110Headlight Wiring Diagram

- 1996 Mazda Protege Wiring Diagram Original

- Ohm Car Audio Wiring Diagrams

- Pioneer Deh 17010Wiring Diagram

- Reverse Light Wiring Diagram Color Code Vw A2

- Ohc Engine Diagram

Explore Topics 5

- Auto Crane 3203Prx Wiring Diagram

- Gm Bose Wiring Diagram

- Continental Plate Diagram

- Subaru Forester Electrical Diagram

- Electrical Wiring Ladder Diagram

- 12Volt Ford Wiring Diagram

- Cat 5 Wiring Diagram Network

- 2005 Ford Pick Up Trailer Wiring Diagram

- 20010Ford Ranger Door Parts Diagram

- 2008 Nissan Sentra Fuse Diagram